Micro- and Meso-Analysis

Description

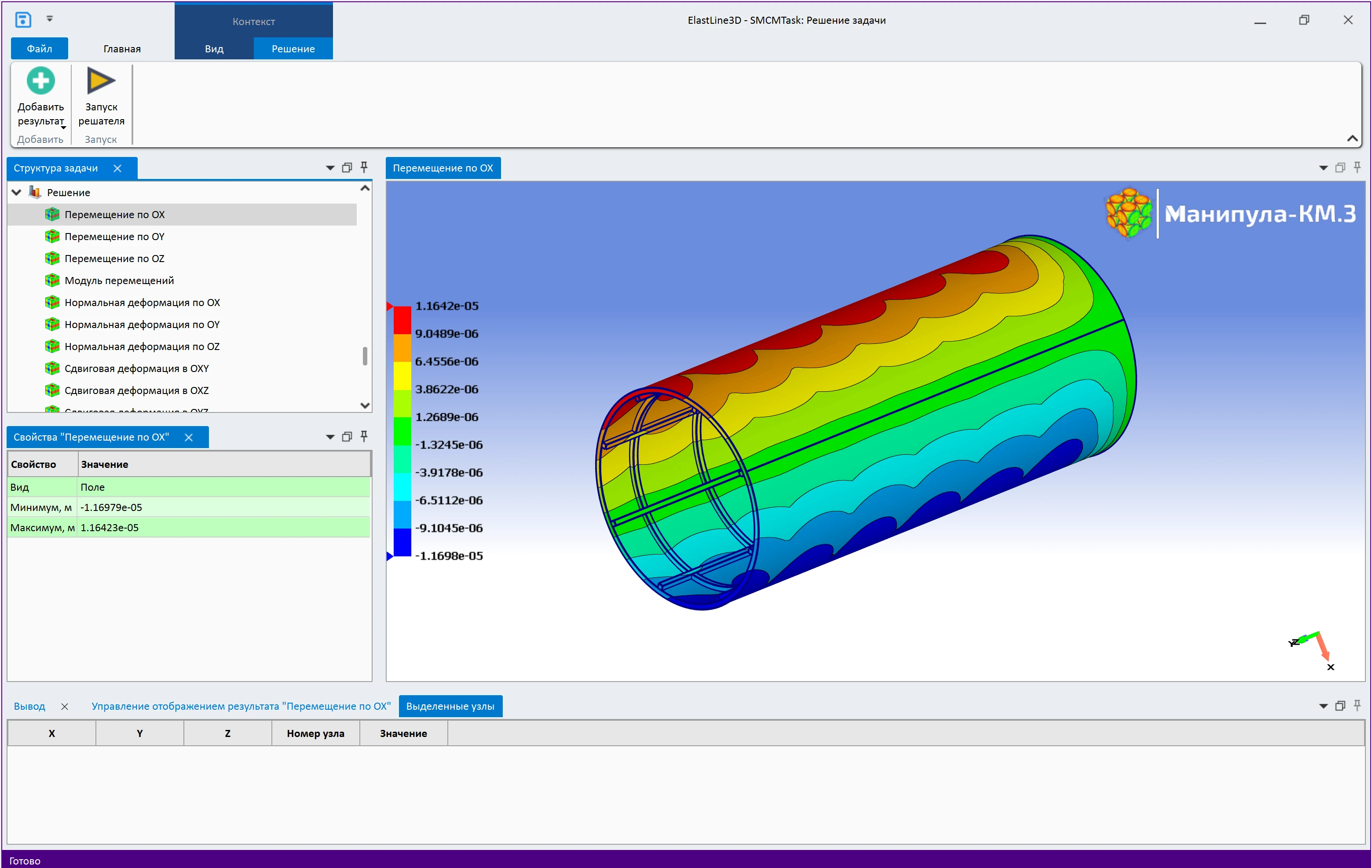

Micro-analysis focuses on studying the microstructural features of materials. This method enables researchers to investigate how microstructure affects the mechanical and physical properties of a material. In the «Manipula» software package, micro-analysis allows modeling material behavior at the microscale — helping to establish the relationship between microstructure and macroscopic properties.

Meso-analysis occupies an intermediate position between micro- and macro-levels of research. It focuses on structural elements of composites that are larger than individual fibers or particles but smaller than the overall dimensions of the structure: reinforcing fillers, interphase layers, manufacturing defects, etc. In the «Manipula» software, meso-analysis enables:

- evaluating the impact of reinforcement architecture (fiber orientation, packing density, weave pattern) on local material properties;

- modeling the interaction of composite components at the representative volume level;

- predicting the initiation and progression of damage (delamination, cracks, debonding) under loading;

- refining effective material properties for subsequent macro-analysis.

In Manipula/SMCM 4.0, modeling of effective properties of composite materials is implemented using the asymptotic homogenization method (homogenization method). Among Russian and international CAE-class software packages, this solution stands out for its comprehensive list of calculated effective composite properties, including:

- linearly and nonlinearly elastic;

- hyperelastic;

- plastic;

- viscoelastic;

- other properties.

All composite material models in Manipula/SMCM 4.0 comply with the Russian national standard GOST R 57700.42‑2023 «Numerical Simulation of Polymer Composite Materials. General Provisions».

Capabilities

- Thermophysical properties of composite materials (CM):

- thermal